Our objective is to provide added value bringing competitiveness to the industry, through machine learning-based failure diagnosis, prognosis and energy efficiency actionable insights.

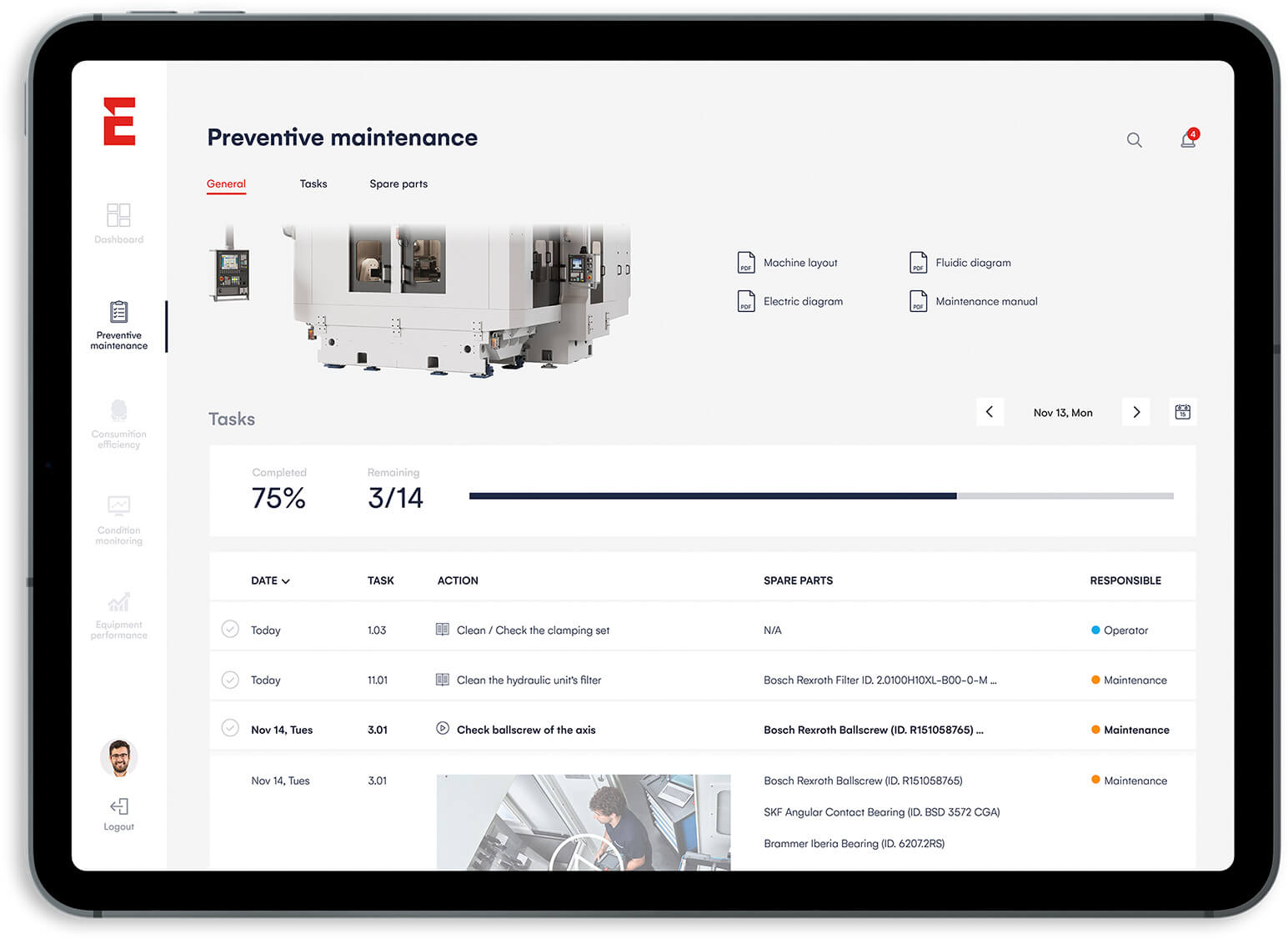

Preventive maintenance

Reducing maintenance costs.

- Dynamic adjustment of maintenance activities

- User guide for maintenance tasks

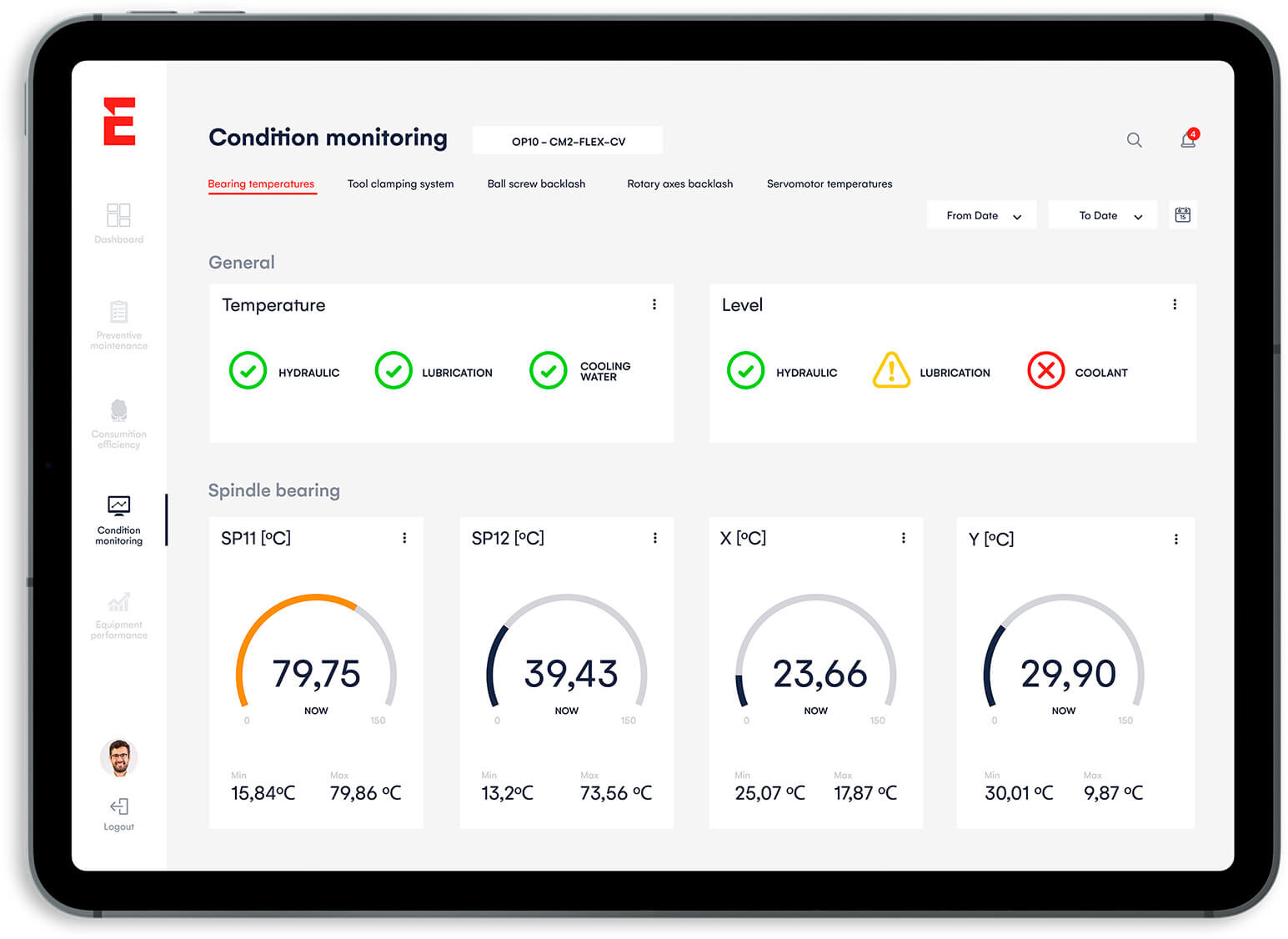

Condition monitoring

Increasing the productivity and the availability: Machine health self assesment (machine fingerprint).

- Spindle bearing condition

- Tool clamping system

- Ball screw backlash condition

- Rotary axes backlash condition

- Servomotor temperatures / torques

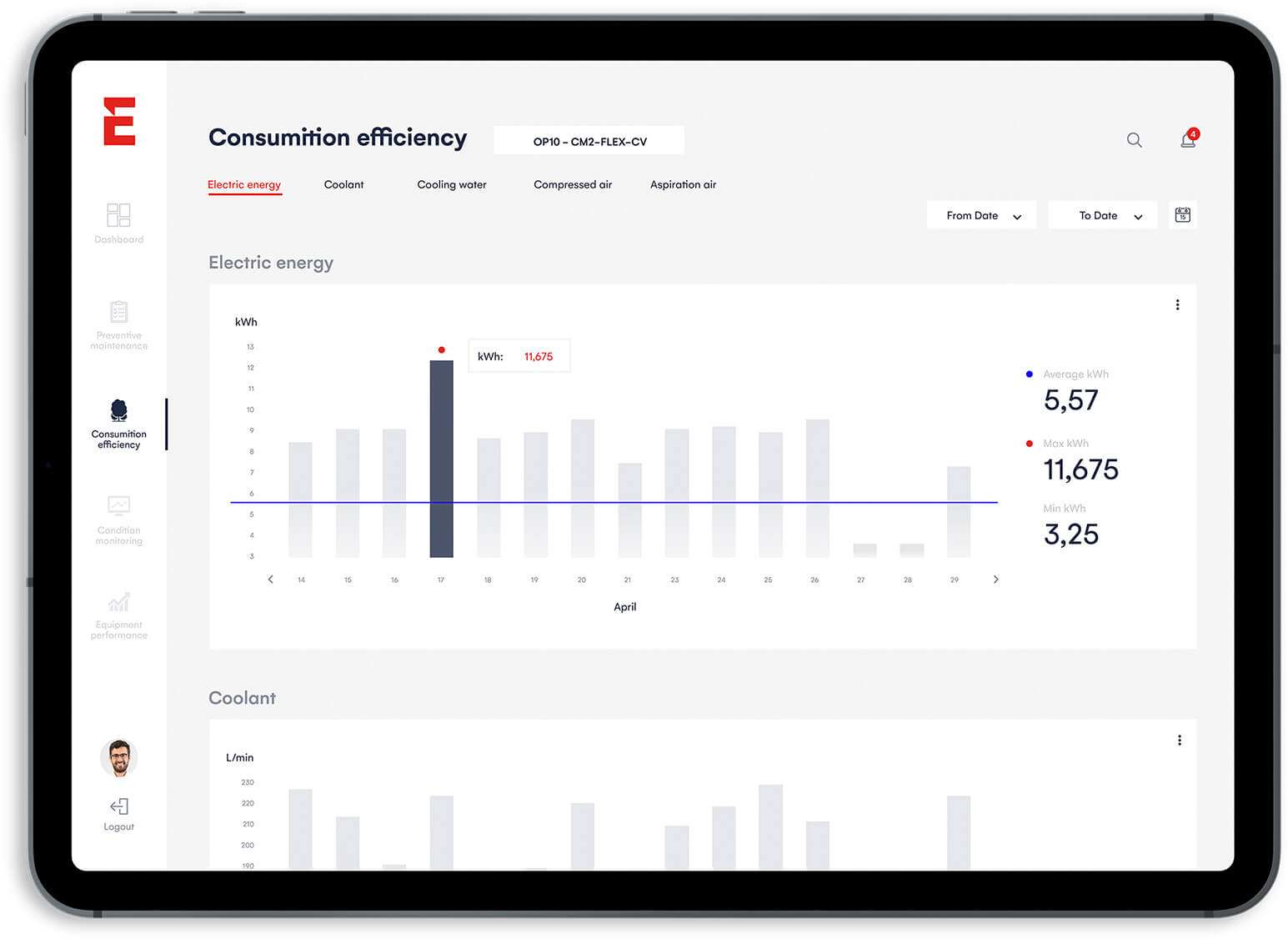

Consumption efficiency

Controlling / Optimizing the utility consumption: Global and per part&model consumption values.

- Electric energy

- Coolant

- Cooling water

- Compressed air

- Aspiration air

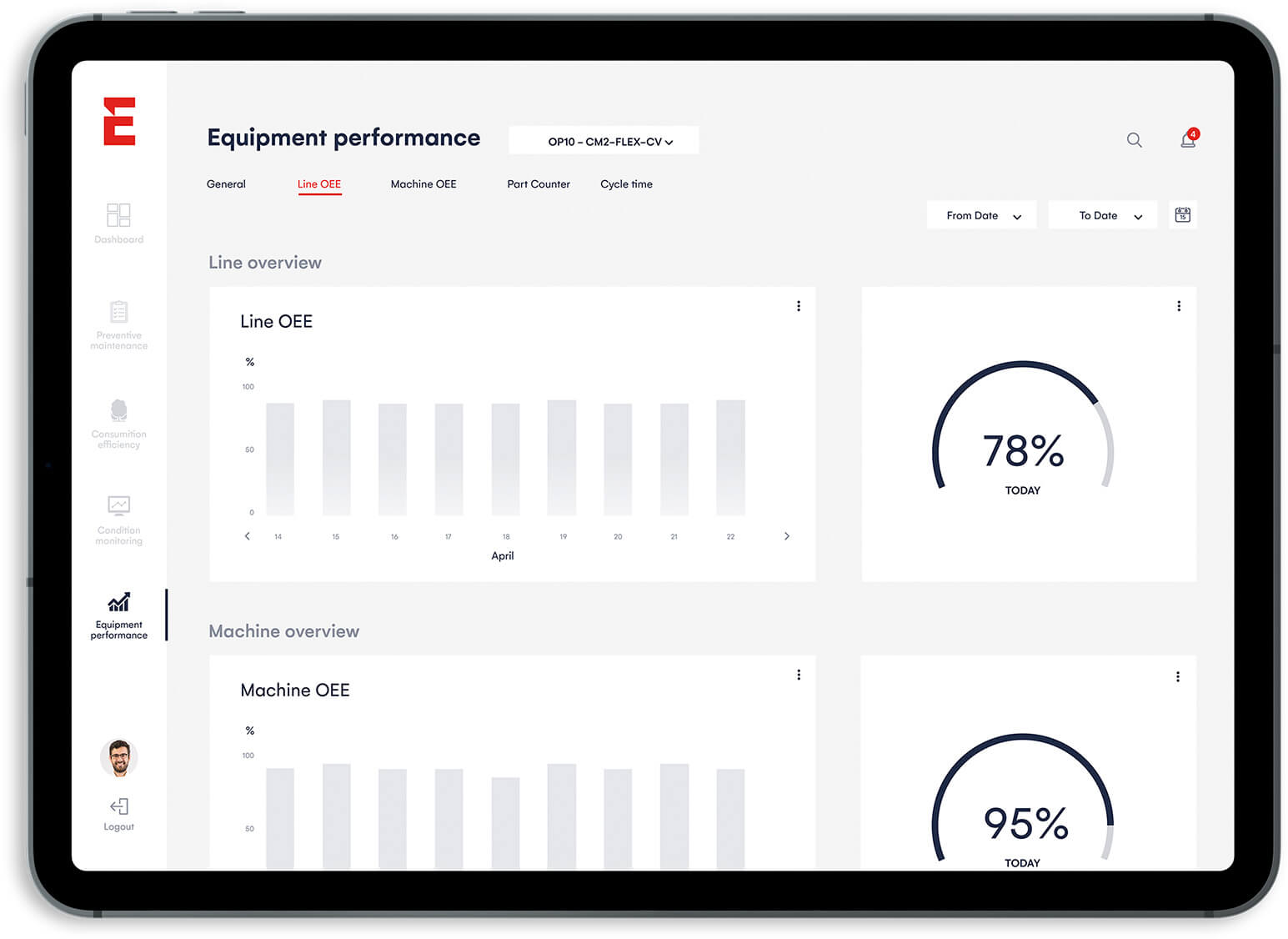

Equipment performance

Controlling / Optimizing equipment performance / availability.

- Intrinsic Machine availability

- Production line availability

- Number of produced parts by model/day

- Machine status reports

How Aingura IIoT produces new knowledge?

- Acquiring massive data from multiple sensors and heterogeneous devices, ensuring data quality with advanced sensor fusion strategies.

- Filtering noise data and variable selection to reduce up to 90% of storage and communication infrastructure needs.

- Developing specially tailored machine-learning algorithms for knowledge discovery and perform Real-Time diagnosis and prognosis.

How Can We Help You ?

Get in touch with us.